Liaoning Duolun Machinery Co., LTD

Add: No 18, Ganquan Road, Zhenxing District, Dandong, Liaoning,China

Tel: 0086- 415- 6181481

Fax: 0086- 415- 6178681

Zip code: 118009

Website: gphjh.com.cn

E-mail: dolun@sohu.com

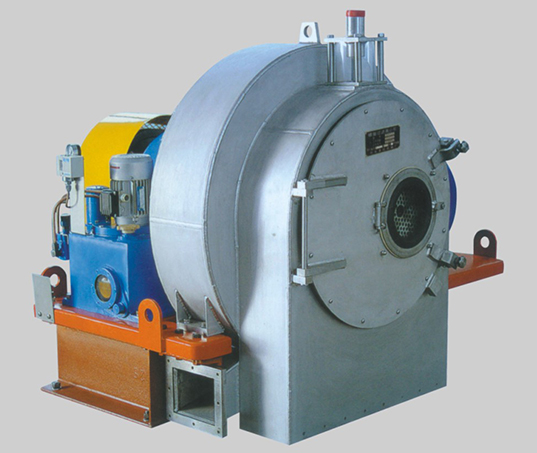

Model: DH450 spiral centrifuge

DH Series horizontal Spiral/ Sieving net Filtration Centrifuge

Structure and Working Principle

Opeartions to suspension such as feeding, dehydrating, washing and discharging etc. can all be processed by DH Series Spiral Screen Filtration Centrifuge at its full speed. Main machine starts with power on and speeds up automatically. Open the feeding valve when predetermined condition is met. Material to be separated enters centrifuge along pipeline and is distributed onto drum wall through feeding holes on the smaller end of spiral wheel. Under the effect of centrifugal force, liquid phase in suspension is thrown out through filtration net and holes on drum wall then discharged from centrifuge, while solid phase remains in the filter net to form a thin filter residue. In the centrifugal force field, filter residue is gradually pushed from small end of the drum to big end by two forces: one component of forces points to the big end paralleled with the drum generatrix, the other is the thrust force from spiral bar’s motion. Filter residue is turned constantly by spiral bar to enhance separating effect. Filter residue out of drum is finally discharged from residue outlet, thus solid-liquid separation is finished.

DH Series Spiral Screen Filtration Centrifuge is a horizontal filtration centrifuge with the function of continuous working, continuous spiral discharging. It is mainly used for separating and dehydrating two–phase suspension with solid-phase grains ranging from 0.05 to 10mm. It is applied in chemical, foodstuff, chemical fiber, mining and metal melting, pharmacy and light industry.

Main Characteristics

Continuous operation, spiral discharging and large output.

High dehydration rate of solid phase, good washing effect and high efficiency.

Tight structure,convenient operation and maintenance.

Material Choice

According to users’requirement, the part contact with liquid of centrifuge are made of austenite stainless steel(321,316L…), Hastelloy alloy, titanic alloy or other anti-erosion materials.

Special allocation

Following allocation is made possible to meet customers’ demand.

1.Frequency conversion plus PLC controlling system.

2.Detecting protection system for vibration and temperature rising.

3.Feeding speed control.

4.Solid-liquid separation device in liquid outlet.

5.Other allocation demands.